Ford Tractor Radiator: Keeping Your Tractor Cool and Running Smoothly

Maintaining your Ford tractor's cooling system is critical. A faulty radiator leads to costly repairs and significant downtime. This guide helps you identify problems, decide between repair or replacement, and perform preventative maintenance to keep your tractor running efficiently. For more information on tractor coolants, check out this helpful resource: Tractor Coolant Guide.

Spotting Trouble: Signs Your Ford Tractor Radiator Needs Attention

A failing cooling system often shows clear warning signs. Overheating, with steam escaping from under the hood or a rapidly rising temperature gauge, demands immediate attention. Inspect the radiator for leaks – even small drips indicate a problem. Low coolant levels, even without visible leaks, are another red flag. Rusty or slimy coolant suggests corrosion. A quick visual inspection can prevent more extensive damage.

Diagnosis: Repair or Replacement?

Proper diagnosis is crucial before starting any repairs. Is the leak minor (a slow drip) or major (a large crack)? The extent of the damage determines the repair approach.

Small leaks might be repairable with radiator sealant – a relatively inexpensive fix. However, significant damage, such as a large crack or substantial corrosion, usually necessitates a complete radiator replacement. While more costly, this prevents potential irreversible engine damage.

Here’s an estimated cost and downtime breakdown:

| Problem | Solution | Estimated Cost (USD) | Estimated Downtime |

|---|---|---|---|

| Minor Leaks/Slow Drips | Radiator sealant, minor leak repair | $200 - $500 | 1-3 days |

| Significant Leaks/Damage | Ford tractor radiator replacement | $800 - $2000 | 3-7 days |

| Coolant Contamination/Sludge | Cooling system flush and complete coolant change | $100 - $300 | 1 day |

Note: These costs are estimates and vary based on tractor model, repair complexity, labor costs, and parts sourcing. Obtain multiple quotes before proceeding.

Fixing Minor Leaks: A DIY Approach

For minor leaks, a DIY repair might be feasible. Follow these steps:

Safety First: Let the engine cool completely to prevent burns. Gather necessary tools: radiator sealant (following manufacturer recommendations), clean rags, gloves, and a funnel.

Locate the Leak: Carefully examine the radiator, using a flashlight if needed, to pinpoint the leak's source.

Apply Sealant: Follow the sealant instructions carefully. This usually involves adding the sealant to the coolant reservoir.

Test the Repair: Run the engine briefly and monitor for continued leakage. Persistent leaks require radiator replacement.

Major Radiator Issues: When to Call a Professional

Radiator replacement is more complex and often best left to experienced mechanics. While DIY is possible, it requires mechanical skills and specialized tools. A professional replacement may involve:

Complete Coolant Drainage: Completely drain the coolant into a designated container for proper disposal. Never dump coolant directly onto the ground.

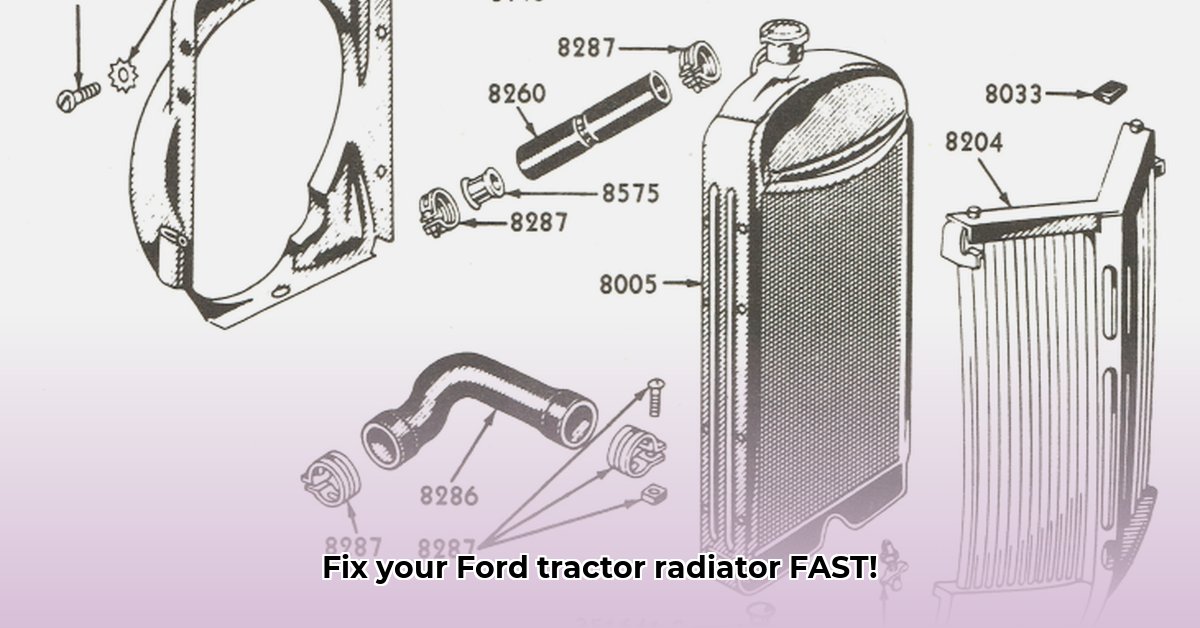

Disconnecting Components: Carefully disconnect all hoses and fittings, labeling each connection for easy reassembly. Photography can aid in this process.

Radiator Removal: This procedure varies by tractor model. Consult your owner's manual for specific instructions. Removal might require removing related parts.

New Radiator Installation: Install the new radiator carefully, ensuring proper alignment. Reconnect all hoses and fittings. Thoroughly check for leaks.

Refilling and Leak Check: Add the correct coolant type and amount (as specified in your owner's manual). Inspect for any leaks.

Preventative Maintenance: Keeping Your Radiator Healthy

Regular maintenance extends radiator lifespan and prevents costly repairs. Consider these steps:

Annual Inspections: Visually inspect the radiator annually for leaks, corrosion, or damage. Check for debris buildup.

Coolant Changes: Follow your owner's manual recommendations for coolant changes. Old coolant loses effectiveness and can become corrosive.

Cleaning: Regularly clean radiator fins using compressed air or a soft brush to remove dust and debris that restrict airflow.

Regular maintenance on your Ford tractor's cooling system is a cost-effective way to ensure smooth operation and avoid costly downtime.

How to repair a leaking tractor radiator cheaply

Key Takeaways:

- Repairing a damaged radiator, instead of replacing it, saves money and reduces waste.

- Soldering provides a reliable but demanding repair. JB Weld offers a simpler, less certain alternative.

- Thorough cleaning is essential for any repair method.

- The best repair method depends on the damage, your skill level, and your tractor's pressure system.

Assessing the Damage: The First Step

Before initiating any repair, carefully examine the radiator. Is it a small pinhole or a larger crack? The damage's size and location determine the repair strategy. Small leaks might be easily fixed. Larger damage often necessitates replacement, which might be more economical than a complex repair. Take photos to aid in documenting the damage.

Repair Method 1: The Soldering Solution

Soldering creates a strong seal but requires skill and tools: a soldering iron, solder, flux, and safety glasses.

- Clean the area thoroughly, removing rust, debris, and old sealant. Use a wire brush and degreaser.

- Apply flux to the damaged area.

- Carefully melt solder around the leak(s), creating a complete seal.

- Allow the solder to cool completely and inspect for weak points.

Pros: Strong, durable repair; cost-effective for significant damage. Cons: Requires skill and specialized tools; time-consuming.

Repair Method 2: The JB Weld Approach (Minor Leaks Only)

JB Weld is easier to use but less reliable than soldering, especially in high-pressure systems.

- Clean the area thoroughly.

- Prepare JB Weld according to the manufacturer's instructions.

- Apply the epoxy evenly over the leak.

- Allow ample curing time (as per product instructions).

Pros: Easy to use; readily available; minimal tools needed. Cons: Less durable than soldering; higher failure risk; ineffective for major damage.

Choosing the Right Method: A Cost-Benefit Analysis

Consider these factors when choosing a repair method:

- Damage Severity: Small pinholes might respond to JB Weld; large cracks require soldering or replacement.

- Skills and Tools: If you lack soldering experience, JB Weld might be a more practical option.

- Tractor Value and Age: Repairing an older tractor is often more cost-effective than replacement.

- Environmental Considerations: Dispose of old coolant and materials responsibly.

Preventative Maintenance: Avoiding Future Leaks

Regularly check coolant levels and look for leaks. Flush and replace coolant as recommended to keep the system clean and extend radiator lifespan. Preventative maintenance saves money and avoids costly repairs.